All Categories

Featured

Table of Contents

- – Mobility Van Repair Near Me Walnut, CA

- – OCRV Center

- – Handicap Van Repair Walnut, CA

- – Van Customization Near Me Walnut, CA

- – Rust Repair Sprinter Van Walnut, CA

- – Mercedes Sprinter Van Repair Walnut, CA

- – Rust Repair Sprinter Van Walnut, CA

- – Rust Repair Sprinter Van Walnut, CA

- – Sprinter Van Repair Shop Near Me Walnut, CA

- – Sprinter Van Service Near Me Walnut, CA

- – Van Customization Near Me Walnut, CA

- – Wheelchair Accessible Van Repair Walnut, CA

- – Van Repair Shops Near Me Walnut, CA

- – Sprinter Repair Shop Near Me Walnut, CA

- – OCRV Center

Mobility Van Repair Near Me Walnut, CA

i Live in Chile, beside Argentina, and have to inform you that OEM windshield is manufactured by Pilkington for my T1N in Argentina, they sold it under their very own brand name as well, the only distinction is that OEM includes a 3 point star, and pilkington is composed smaller sized, i believe that vanished your questions.

Sadly we do not have any type of pictures of the application procedure, since the bed lining is incredibly sticky and gets almost everywhere. It was impossible for us to use our camera. First we applied the bed liner with brushes in the difficult to reach places-- anywhere the roller would not get to. With the brushes, you require to utilize a swabbing as opposed to a brushing strategy so as to get the correct structure.

After the difficult to reach areas all had one layer, we returned and did a 2nd coat again with the brushes. The directions say to wait 15 mins prior to using a second layer, however we had the ability to give it even more time to completely dry. By the time we had actually finished one side of the van the other side had already been drying for about 30 minutes.

Again we had the ability to function without awaiting the bed lining to completely dry, because by the time we had actually applied the initial coat to 2nd side of the van, the opposite's initial coat was dry adequate to use the 2nd layer. Once the 2nd coat was dry on the whole van, we did a bit of retouching anywhere the structure had not been quite ideal.

Handicap Van Repair Walnut, CA

Sprinter vans are a trustworthy and important investment, yet like any automobile, they need treatment and focus. By staying positive with maintenance and repairs, you can maintain your Sprinter running smoothly for years to come.

Frequently, when these vans are developed, you can get little plates of steel back there that can rust. This isn't certain to the Revel; it's something you ought to check on Sprinter vans.

Van Customization Near Me Walnut, CA

You'll locate little locations holding screws. Utilize a Flathead screwdriver or a tiny pick device to pop these plastic covers off. Beware, as they can fly off. You'll need to eliminate these covers and proceed along, popping them out. It's helpful to have pliers, though I don't have mine with me today.

You might discover extra screws under the flooring mat holding down the back of the van that need to be gotten rid of. There are a couple of screws on the back displays that need to be eliminated.

As I stated, little bits of metal can get deposited back right here throughout the van's building, creating chances for corrosion. This isn't as well bad contrasted to the majority of vans I've seen, but it's still worth pulling this off and cleaning it.

This helps to cleanse the location extensively. For corrosion elimination, I advise making use of Rust-Oleum Rust Agitator, among my preferred items. Spray it on the places where rust has begun to develop, especially in the edges. This item transforms and counteracts the rust. Because this will certainly be under the black plate, it will not be noticeable.

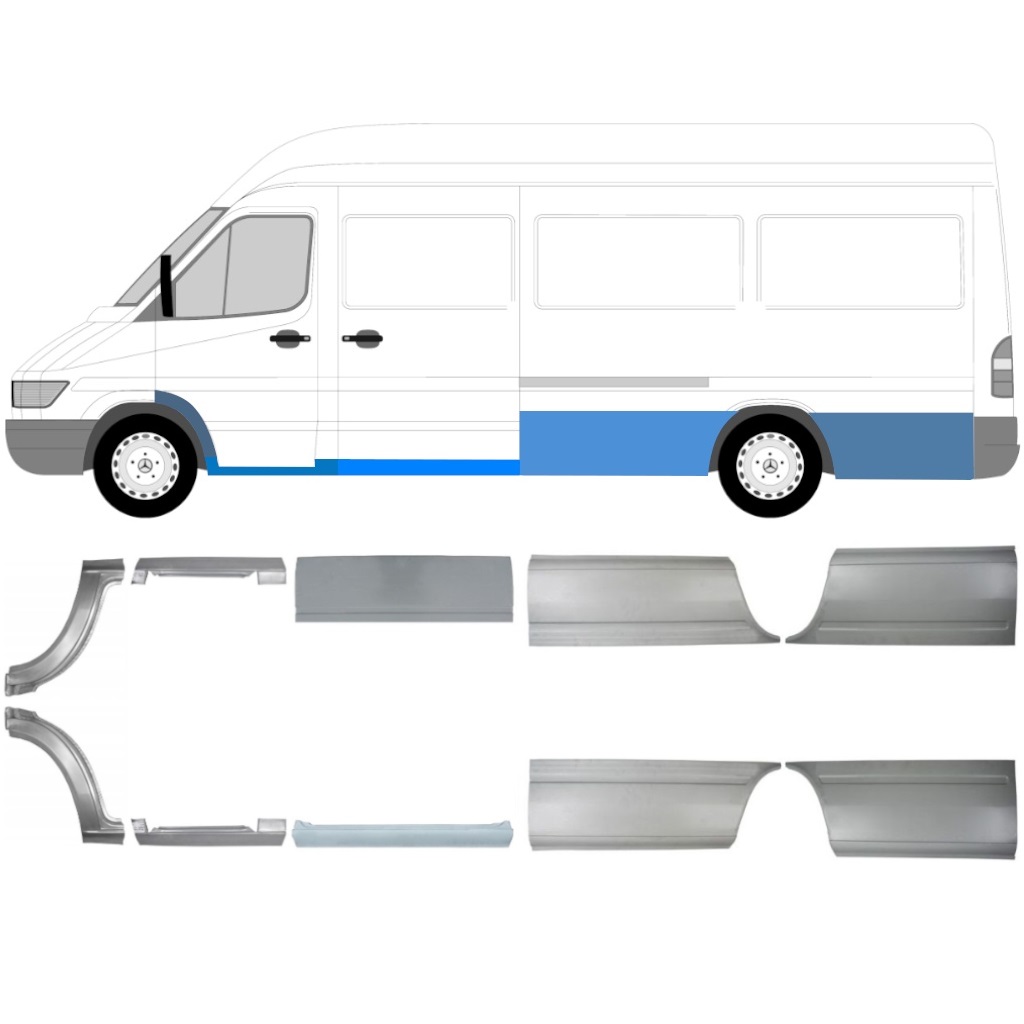

Rust Repair Sprinter Van Walnut, CA

With many of the corrosion taken care of, reassembly is just the reverse of the removal procedure. Although it was a bit complicated to re-install the plastic item, it called for levering the backside in initially, getting it under the plywood, and after that snapping it right into area with a flathead screwdriver (Sprinter Van Service Near Me Walnut).

It was a little bit fiddly, however I managed to break it all back in location. After that, you require to drop the plastic screws back in with the tabs facing the rear of the van. Lastly, break the other pieces back right into location. Currently you have the peace of mind knowing there's no rust under your rear trim.

Mercedes Sprinter Van Repair Walnut, CA

Provide us a telephone call at (866) 695-8267 and we'll enjoy to help you. No phone call centers, no out of state agents - just our van experts at our HQ in Arizona. Extra soon, John Willenborg.

We recognized about this when we obtained the van, & had actually agreed that we would obtain new doors if we truly had to. Andrew chose to make an attempt at repairing them up himself, and for that reason saving us a bit cash! Even if the 'repair' lasts for a couple of years, & we ultimately need to obtain a brand-new door/s, then at the very least it saved us some money in the start of our conversion which we can invest in another thing.

Although we create our blog to help others with their build & suggest items & materials that we have used - please constantly do plenty of study and do pick approaches that you really feel comfy with & that fits your van build & requires! Our Moving Door Prior to we fixed it EEEK !! Disclaimer: This site consists of associate web links as part of the Amazon Associates Program.

As soon as we were pleased we had actually gotten rid of as high as we could, we then fined sand any kind of areas of rust to the bare steel, utilizing our detail sander. We utilized After we would certainly ended up sanding, we then used the to deal with the corroded places on both our back door and our moving door.

Rust Repair Sprinter Van Walnut, CA

Next we appliedfor the holes. We then sanded that down by hand once it had hardened, utilizing Then we grabbed the and used it. Once it had hardened we scrubed it down with Aluminium mesh moulded to the form of the door This is what the ISOPON looks like when it has actually set The last action was simply to use two coats of grey guide complied with by two layers of We did this action on both our back entrance and moving door.

I began my horticulture company with a 2004 transportation T280 85PS SWB.It was offered to me with 6 months MOT.However - prior to I utilized it, I removed the front end off the van, front light panel, wings, bumper - the whole lot. And I removed the total cab interior - seating, dashboard, floor mats - all of it.

Rust Repair Sprinter Van Walnut, CA

Both Side steps - no much longer existed, however they are hidden by the plastic step covers - so one would never know unless you offer a great excavating from beneath. Fitted new steps, new inner sills, new outer sills.

I have actually been an auto mechanic for 27 years - and Transits are absolute rust buckets. Below they are the worst for rot versus any kind of other van.

Sprinter Van Repair Shop Near Me Walnut, CA

Every other Merc Sprinter marketed has 250,000 to 450,000 miles on it, which indicates they appear to have no worry covering the miles, where as every various other Transportation advertised - is either a blown engine or just had a replacement engine. They all leakage oil once they get passed 100,000 miles.

The engine was utilized in Jaguar X Kind, Mondeos, Land Rover Defenders, - all leakage oil from the front oil filter housing area. The Merc is a much superior drive to the Transits. So I chose a 114,000 mile, 2013MY, Sprinter CD313 LWB.Had a tow bar fitted so I might draw my trailer.

I discover I am getting frustrated with automobiles slowing my progression. The space in the taxicab is also much premium to the Transportation. Even more leg area to go into the taxicab both for the driver or the passengers. Transits appear to knock the dashboard up near to you. Much more storage area by miles in the Merc over the Transportation, in the doors, under the seats and over the head.

Sprinter Van Service Near Me Walnut, CA

Merc provide you two storage space boxes under the seats. And the doors have added storage space under the required door pockets. For me its a Mercedes Sprinter - later ones should not be as poor as very early Sprinters. They will last better on the underside, yet easier to track corrosion on the top, and fixing.

- lease a brand-new vehicle and transform it every 3 or 4 years - obtain any type of make you want - as it will have warranty, yet you angle stay clear of down time from your company whilst you have a van in for mechanical or electric fixings even under service warranty. That's my point of view

I might be inaccurate - and I will have a pail of rust in twelve month - see this area.

We knew regarding this when we got the van, & had agreed that we would certainly get brand-new doors if we really needed to. Andrew determined to make an effort at repairing them up himself, and consequently saving us a little bit money! Even if the 'repair' lasts for a number of years, & we ultimately have to get a brand-new door/s, after that at the very least it conserved us some money in the beginning of our conversion which we might invest on another thing.

Van Customization Near Me Walnut, CA

We are not specialists (just first-time van home builders!), & we are simply sharing what we have chosen to do & what has actually helped us after hours of research study. So although we write our blog site to aid others with their construct & recommend products & products that we have utilized - please constantly do a lot of study and do select techniques that you feel comfy with & that suits your van build & needs! Our Moving Door prior to we repaired it EEEK !! Please note: This website has affiliate links as part of the Amazon Associates Program.

When we were satisfied we had actually eliminated as much as we could, we after that sanded any type of areas of corrosion to the bare metal, utilizing our detail sander. We made use of After we would certainly ended up sanding, we after that used the to treat the rustic places on both our back entrance and our moving door.

Wheelchair Accessible Van Repair Walnut, CA

Next we appliedfor the holes. We after that sanded that down by hand once it had hardened, using After that we got the and used it. Once it had actually set we rubbed it down with Aluminium mesh molded to the shape of the door This is what the ISOPON looks like when it has actually set The final action was simply to apply 2 coats of grey guide followed by two layers of We did this action on both our back door and gliding door.

At Bumper And Also Autobody, we specialize in Sprinter rust repair work, particularly around the windshield area. Below's our procedure: Eliminate the windshield to reveal all concealed corrosion.

Van Repair Shops Near Me Walnut, CA

Re-install the windscreen utilizing factory-grade materials and treatments. Corrosion around the windscreen doesn't just look badit gets worse over time.

When I began residing in my van full-time, I was so stoked to strike the roadway that all I had was a system for my bed and some marginal storage space.

Sprinter Repair Shop Near Me Walnut, CA

The typical hardener isn't much use in UK winters in unheated workshops. The alu includes enhanced obstacle effect and even more resistance to cathodic debonding. You can make use of Colad mixing cups to mix it (3.5:1 proportion), use the 7:1 scale after that add 10% additional hardener in the thinners column which obtains you 7:2 (like 3.5:1) near as darn.

OCRV Center

Address: 23281 La Palma Ave Yorba Linda, CA 92887Phone: (714) 909-1444

Email: art@ocrvcenter.com

OCRV Center

Clearly depends on the devices you have however essentially go for St3 surface preparation. St2 is the bare minimum. I would certainly use a rust awesome type product in the joint just, worked in well, then go once again with the wire wheel. I use 45% phosphoric acid typically, work it in allow it dry in the seam then cable wheel out once again, after that blast it out with brake cleaner yet any kind of great corrosion killer or converter need to do the task.

Van Repair Walnut, CARust Repair Sprinter Van Walnut, CA

Sprinter Van Repair Shop Near Me Walnut, CA

Wheelchair Van Repair Near Me Walnut, CA

Sprinter Van Repair Walnut, CA

Van Customization Near Me Walnut, CA

Mercedes Sprinter Repair Near Me Walnut, CA

Sprinter Repair Shop Near Me Walnut, CA

Handicap Van Repair Walnut, CA

Mercedes Benz Sprinter Repair Walnut, CA

Mercedes Benz Sprinter Repair Walnut, CA

Mercedes Benz Sprinter Repair Walnut, CA

Van Repair Shops Near Me Walnut, CA

Mercedes Sprinter Repair Near Me Walnut, CA

Handicap Van Repair Near Me Walnut, CA

Rust Repair Sprinter Van Walnut, CA

Van Repair Shop Near Me Walnut, CA

Van Repair Shops Near Me Walnut, CA

Sprinter Van Repair Shop Near Me Walnut, CA

Sprinter Van Service Near Me Walnut, CA

Mercedes Sprinter Van Service Walnut, CA

Sprinter Van Repair Near Me Walnut, CA

Van Repair Walnut, CA

Wheelchair Van Repair Near Me Walnut, CA

Wheelchair Van Repair Shops Near Me Walnut, CA

Handicap Van Repair Walnut, CA

Sprinter Repair Near Me Walnut, CA

Wheelchair Van Lift Repair Near Me Walnut, CA

Handicap Van Repair Walnut, CA

Sprinter Repair Shop Near Me Walnut, CA

Sprinter Van Repair Shop Near Me Walnut, CA

Mercedes Sprinter Repair Near Me Walnut, CA

Van Customization Near Me Walnut, CA

Sprinter Van Service Near Me Walnut, CA

Wheelchair Van Repair Shops Near Me Walnut, CA

Handicap Van Repair Shop Walnut, CA

Van Repair Shops Near Me Walnut, CA

Van Repair Shop Near Me Walnut, CA

Wheelchair Van Lift Repair Near Me Walnut, CA

Handicap Van Repair Shop Walnut, CA

Sprinter Van Repair Near Me Walnut, CA

Handicap Van Repair Shop Walnut, CA

Van Repair Shop Near Me Walnut, CA

Sprinter Van Repair Near Me Walnut, CA

Sprinter Repair Shop Walnut, CA

Wheelchair Accessible Van Repair Walnut, CA

Sprinter Van Repair Near Me Walnut, CA

Sprinter Repair Shop Walnut, CA

Rust Repair Sprinter Van Walnut, CA

Sprinter Van Repair Near Me Walnut, CA

Sprinter Van Repair Shop Near Me Walnut, CA

Handicap Van Repair Near Me Walnut, CA

Wheelchair Accessible Van Repair Walnut, CA

Sprinter Van Service Centers Walnut, CA

Sprinter Repair Shop Near Me Walnut, CA

Mercedes Sprinter Van Repair Near Me Walnut, CA

Wheelchair Accessible Van Repair Walnut, CA

Wheelchair Van Repair Near Me Walnut, CA

Mercedes Sprinter Van Repair Near Me Walnut, CA

Sprinter Van Repair Near Me Walnut, CA

Mercedes Sprinter Van Repair Walnut, CA

Sprinter Repair Shop Walnut, CA

Mobility Van Repair Near Me Walnut, CA

Sprinter Repair Walnut, CA

Mercedes Sprinter Van Service Walnut, CA

Mercedes Sprinter Van Service Walnut, CA

Sprinter Repair Shop Walnut, CA

Mercedes Sprinter Van Repair Near Me Walnut, CA

Sprinter Van Repair Walnut, CA

Van Customization Near Me Walnut, CA

Mercedes Sprinter Van Service Walnut, CA

Sprinter Repair Walnut, CA

Sprinter Van Service Near Me Walnut, CA

Van Repair Walnut, CA

Mercedes Sprinter Van Service Walnut, CA

Handicap Van Repair Near Me Walnut, CA

Sprinter Van Repair Walnut, CA

Sprinter Repair Shop Near Me Walnut, CA

Find A Seo Companies Walnut, CA

Around Here Seo Company Near Me Walnut, CA

OCRV Center

Table of Contents

- – Mobility Van Repair Near Me Walnut, CA

- – OCRV Center

- – Handicap Van Repair Walnut, CA

- – Van Customization Near Me Walnut, CA

- – Rust Repair Sprinter Van Walnut, CA

- – Mercedes Sprinter Van Repair Walnut, CA

- – Rust Repair Sprinter Van Walnut, CA

- – Rust Repair Sprinter Van Walnut, CA

- – Sprinter Van Repair Shop Near Me Walnut, CA

- – Sprinter Van Service Near Me Walnut, CA

- – Van Customization Near Me Walnut, CA

- – Wheelchair Accessible Van Repair Walnut, CA

- – Van Repair Shops Near Me Walnut, CA

- – Sprinter Repair Shop Near Me Walnut, CA

- – OCRV Center

Latest Posts

Hot Water Heater Replacement La Jolla

Tankless Water Heater Repairs Near Me Del Mar

Electric Tankless Water Heater Installers Tierrasanta San Diego

More

Latest Posts

Hot Water Heater Replacement La Jolla

Tankless Water Heater Repairs Near Me Del Mar

Electric Tankless Water Heater Installers Tierrasanta San Diego