All Categories

Featured

Table of Contents

- – Kitchen Hood Service Toluca Lake, CA

- – Instant Air Solutions

- – Hood Filter Cleaning Toluca Lake, CA

- – Kitchen Hood Inspection Toluca Lake, CA

- – Kitchen Hood Service Toluca Lake, CA

- – Restaurant Hood Installation Toluca Lake, CA

- – Commercial Hood Cleaning Service Toluca Lake...

- – Professional Hood And Duct Cleaning Toluca L...

- – Hood Cleaning Companies Toluca Lake, CA

- – Kitchen Exhaust Cleaning Service Toluca Lake...

- – Restaurant Hood Cleaning Service Toluca Lake...

- – Fire Suppression System Certification Toluca...

- – Kitchen Exhaust Fan Repair Service Toluca La...

- – Hood Filter Replacement Toluca Lake, CA

- – Fire Suppression System Certification Toluca...

- – Instant Air Solutions

Kitchen Hood Service Toluca Lake, CA

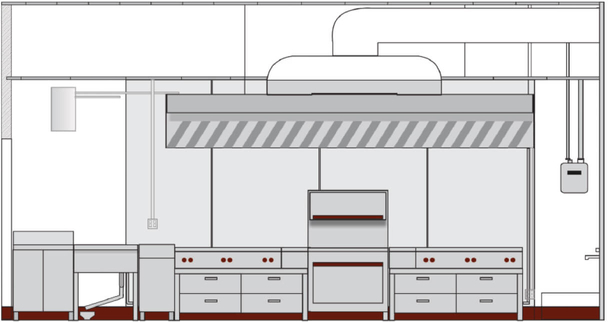

So, you don't require to bother on your own with all these technological codes and standards, we'll manage it for you. Exhaust hoods can be categorized based on their applications and setup arrangements. At NFP, we offer top-grade array hoods for any kind of application and configuration. Here are a few of them. Type I hoods are necessary for any kind of cooking home appliance that produces grease-laden vapors, such as fryers and grills.

They're normally equipped with a fire suppression system too. Their make-up air systems regularly bring fresh air in to replace the exhausted air and preserve pressure balance. These hoods can not deal with oil, so they're installed above ovens, cleaners, and any kind of various other non-grease-producing appliances. Type II hoods get rid of warm, steam, and odors from the air and supply a much more comfortable atmosphere.

Hood Filter Cleaning Toluca Lake, CA

In industrial kitchen areas, it's typical that some food preparation devices are positioned in the center of the kitchen area, not versus a wall surface. Hoods (kind I, II, and ventless) are put on hold from the ceiling right above the cooking equipment to offer efficient coverage. Correct installment and considering good architectural assistance are necessary to make certain the hood is firmly connected and can be used without any type of trouble

They're placed closer to the surface of the cooking tools for a much more reliable exhaust of oil vapors and damaging fumes. Also, they have a tendency to take less space and this has actually made them a fantastic choice for locations with restricted space, such as food trucks.

Because of this accumulation, many dining establishment kitchen areas install a kitchen hood. Alturas specialists assist you do simply that, with a team of hood installers in Los Angeles.

Kitchen Hood Inspection Toluca Lake, CA

Below are some of the factors to take into consideration before you speak to a handyman for hood installment. If you are a brand-new dining establishment proprietor, and seeking commercial hood installation companies near you in Los Angeles, this checklist will assist you locate the ideal one. Make certain to hire licensed service technicians that understand dining establishment air flow systems.

Employ somebody that currently has experience with the leading commercial hood brands that you are thinking about. Security is one of the important elements to consider for Kitchen ventilation.

To stay clear of oil fires, Kind 1 kitchen area hoods should be cleansed regularly. The condensate hoods are additionally acknowledged as Kind 2 Business kitchen Hoods. They're made to collect and get rid of moisture, scents, warmth, vapor, and vapor from non-grease-producing appliances. Stoves, coffee makers, business dish washers, and so on, are all examples of this.

Kitchen Hood Service Toluca Lake, CA

Condensate hoods do not include an oil filter and are usually manufactured from galvanized air ducts as opposed to welded. The exhaust air flow and how it's managed are vital factors to consider. Installation prices for a ductless system are reduced than for an aired vent exhaust-style system with ductwork, depending upon the exhaust ventilation system you select.

Consequently, they're less costly than a Kind I hood with an exhaust system. Ductless exhaust systems are likewise not suitable for everybody. They eliminate irritants from the air before returning the clean air to the kitchen area. Finally, a system similar to this should not be utilized in a kitchen area that generates a lot of grease.

Professional setup of ventilation systems, consisting of kitchen area hoods and commercial hoods, is crucial to guarantee proper airflow and safety in business cooking areas. The hood setup process includes careful planning and adherence to local codes, and it calls for professional expertise to install a business kitchen area air flow system properly.

We provide a listing of air flow services in dining establishments, offices, supermarkets, and medical facilities. Feel complimentary to obtain in touch with us for business hood setup estimates.

Restaurant Hood Installation Toluca Lake, CA

Mounting a hood system in a dining establishment on your own could not be the ideal concept. We suggest you contact business hood installation firms to aid you.

With the aid of a professional kitchen area hood installer or HVAC technician, installing a cooking area hood for a restaurant should not take longer than 60 mins. In some cases, depending upon the requirements in a commercial setup, it may take longer. It is best to seek advice from a service technician for an on-site quote prior to vent hood or array hood installation.

They need to follow criteria. They must also include: Fire suppression systemsGrease filtersExhaust fans with ductwork These hoods are utilized for home appliances that discharge warm or heavy steam however not oil, such as dishwashers and ovens. They lack fire reductions but need reliable air capture. Kind of food preparation equipmentVolume and intensity of cookingLocal codes and fire risk analyses Oversizing wastes power, undersizing dangers non-compliance.

: These are the most common kind of industrial kitchen exhaust hoods, usually attached to the wall over the stove and vented outside. Constructed from stainless-steel, they are resilient and personalized for any type of kitchen area layout.: Suspended from the ceiling over an island or free standing cooktop, these hoods need extra effective air flow and often tend to be a lot more costly because of their architectural requirements.: The least common in industrial settings, these are placed under a cupboard or countertop.

Commercial Hood Cleaning Service Toluca Lake, CA

When installing a kitchen area hood, it's vital to use corrosion-resistant ductwork that holds up against the greasy and humid kitchen area setting. All electric elements must be GFCI-protected to boost safety and security. In addition, make certain the ductwork format permits very easy access for routine maintenance and cleansing - Toluca Lake Kitchen Hood Service. Many states now call for that all fire suppression systems be, using damp chemical agents especially made for oil fires.

Prior to installment, it is very important to collaborate with the local fire marshal and building division. Prepare and submit a thorough MEP (Mechanical, Electric, Plumbing) plan to help with a smooth allowing process and make certain regional code compliance. To preserve optimal performance, tidy grease filters at the very least regular, or more often depending on cooking volume.

Professional Hood And Duct Cleaning Toluca Lake, CA

A is required for home appliances that produce grease and smoke (e.g., fryers, grills, griddles). Constantly check neighborhood fire and building codes for particular needs.

As a rule of thumb, the hood ought to of the devices and offer sufficient air movement for reliable air flow and code compliance. need to include a, developed particularly for oil fires. These systems have to be skillfully based on guidelines.

All restaurants, whether they are commercial chain restaurants or any type of family-owned walk-in restaurants must carry out measures to take care of airflow better. Business kitchen ventilation systems also referred to as restaurant hoods play a critical role in successfully distributing the air within cooking locations. Their primary function is to efficiently remove smoke and odours that are created during the food preparation procedure.

Hood Cleaning Companies Toluca Lake, CA

It can be challenging to identify the ideal area, installing the air flow hood, and connecting the ductwork. These commercial cooking area hoods are all important parts of your industrial kitchen area ventilation system.

There are 2 primary factors why you would certainly need to install a Dining establishment hood. The very first is to replace an old restaurant hood, and the 2nd is to component of a brand-new commercial dining establishment hood system you are mounting. Whatever your inspiration for installing a new dining establishment hood, the much more prepared you are, the easier your setup will certainly be.

Kitchen Exhaust Cleaning Service Toluca Lake, CA

It is crucial to always take into consideration employing a registered contractor when taking care of the Dining establishment Hood. Sometimes, an unskilled installment could possibly void the warranty terms. Afterwards, you must place the restaurant hood in a space large enough to lay air duct with couple of obstacles and away from combustible products.

You have to consider using protective goggles, steel-toed footwear, gloves, and earmuffs to reduce the risk of any type of kind of injury. Once you have actually received the fully protected Dining establishment hood installation, it is crucial to unbox it with care. Make sure to avoid bending, scratching, or denting any kind of component of the hood throughout the unboxing procedure.

For that, inspect the nameplate specifications and the invoice for all other components to guarantee you received the appropriate tools. If problems occur, call the supplier. Prior to mounting, assess the restaurant hood layout for manufacturing facility designs. To position the restaurant hood assembly according to the final format, you can utilize the flooring.

These changes need to be made by the requirements given in the hood weight index, which can be discovered in the installation guidebook. Make use of a 1/2-inch threaded pole placed to the roof covering architectural beams for hanging the dining establishment hood. Use a power vehicle driver to pierce 9/16-inch holes into the roofing structural beams, straightening with the air flow hood's angled mounting braces.

Restaurant Hood Cleaning Service Toluca Lake, CA

Install a 1/2-inch threaded rod in between installing braces on the air flow hood and structural beam of lights. Safeguard the pole using fender washers and nuts. Bonded the exhaust duct to the air flow hood while it's on the flooring. Guarantee a total weld to stop leaks, consisting of at the connection point between the restaurant hood and exhaust collar.

Setting the 1/2-inch threaded rods about 1/2 inch closer to the back wall surface leading hanger to straighten the air flow hood flush versus the wall. Confirm that the ventilation hood hangs degree. Mount oil filters, oil mugs, and lights into the ventilation hood. Apply stainless-steel gloss to eliminate built up grit and grime from the restaurant hood.

Practical for you: Total Dining Establishment Ventilation System Guide It is without a doubt that your industrial dining establishment hood will certainly constantly come with a whole set of comprehensive directions from the maker to let you know just how to mount a dining establishment hood. While handling your follower, attempt not to raise it by the follower hood.

Attempt to manage it with care to protect against damage to both your follower along with your roof covering. In case you currently do not have actually one mounted, you will certainly require to set up a roofing system aesthetic all from scratch. Follow the manufacturer's standards and guidelines for securing the curb to the rooftop.

Fire Suppression System Certification Toluca Lake, CA

Throughout the procedure of setup, you might first require to make certain that your power source is compatible with the demands of your business dining establishment hood. Always try to make certain that you constantly disconnect the power supply prior to beginning any type of work on or near a dining establishment hood. It would constantly be a great concept to secure the power line to stay clear of any type of unintended contact with sharp objects or devices.

This indicates that you may spend a lot more than the rate approximated above if you are taking into consideration a high-end commercial array hood for your kitchen area. The quantity of food preparation you would intend to do would certainly also aid to identify the devices you need to buy for your kitchen. You can constantly select to opt for a general-purpose industrial array in case you plan to do a great deal of cooking and cooking which can cost anywhere between $1100 and $10,000.

Kitchen Exhaust Fan Repair Service Toluca Lake, CA

To cleanse your kitchen air most successfully, purchase a ducted array hood. Instead of transfer the food preparation exhaust, it will certainly leave it from your home completely. As a whole, most installations need a distance from 20 to 24 in between the base of the hood and the food preparation surface. Over a gas array, this distance needs to be between 24 and 30, unless or else specified.

After that, utilize a degreasing option to tidy surfaces, rinse extensively, and reinstall filters.

Hood Filter Replacement Toluca Lake, CA

A kitchen hood must be installed directly over the cooking home appliances, however the specific positioning depends on the hood design and the devices under it. Once you've picked your commercial cooking area hood, you need to obtain it along with any kind of necessary installation hardware.

Begin by noting the area where the hood will certainly be mounted. Make certain the hood is perfectly leveled. Use mounting braces to protect the hood to the wall surface or ceiling, depending on your design. It's recommended to have an expert or somebody with strong DIY abilities do this. The ductwork connects the hood to the exhaust follower.

Ensure the ducts are mounted to air vent the exhaust air exterior of the structure. The exhaust follower needs to be installed on the outside wall or roofing system, and attached to the ductwork originating from the hood. See to it it's mounted effectively to ensure that it properly gets rid of smoke, heat, and smells.

Keep in mind, these are basic steps and could vary based on the specific type of hood and local guidelines. In the procedure of setting up an industrial kitchen, you'll unavoidably experience the demand for a commercial-grade ventilation hood.

Fire Suppression System Certification Toluca Lake, CA

Mounting an industrial kitchen hood is a task that should not be attempted without professional aid. The journey towards installation should begin with a consultation with an expert hood maker.

Instant Air Solutions

Address: 412 W Dryden St Apt 6 Glendale, CA 91202Phone: (747) 307-6363

Email: instantairsolutionsinc@gmail.com

Instant Air Solutions

Inadequate setup could trigger air leaks, endangering the hood's efficiency and possibly developing fire risks. By collaborating with skilled professionals, you can guarantee your hood is mounted to conform with sector criteria and ideal practices.

Restaurant Hood Installation Toluca Lake, CACommercial Kitchen Hood Installation Toluca Lake, CA

Hood Filter Replacement Toluca Lake, CA

Restaurant Hood Cleaning Near Me Toluca Lake, CA

Professional Hood And Duct Cleaning Toluca Lake, CA

Kitchen Hood Inspection Toluca Lake, CA

Kitchen Hood Repair Service Toluca Lake, CA

Restaurant Hood Installation Toluca Lake, CA

Commercial Hood Cleaning Service Toluca Lake, CA

Commercial Kitchen Hood Installation Toluca Lake, CA

Kitchen Exhaust Cleaning Toluca Lake, CA

Commercial Kitchen Ventilation Toluca Lake, CA

Commercial Kitchen Ventilation Services Toluca Lake, CA

Restaurant Hood Cleaning Service Toluca Lake, CA

Commercial Kitchen Hood Cleaning Toluca Lake, CA

Kitchen Hood Service Toluca Lake, CA

Commercial Kitchen Ventilation Services Toluca Lake, CA

Kitchen Hood Repair Near Me Toluca Lake, CA

Kitchen Exhaust Fan Repair Service Toluca Lake, CA

Restaurant Hood Cleaning Near Me Toluca Lake, CA

Fire Suppression System Inspection Toluca Lake, CA

Kitchen Hood Service Toluca Lake, CA

Commercial Hood Cleaning Service Toluca Lake, CA

Kitchen Hood Repair Near Me Toluca Lake, CA

Kitchen Exhaust Cleaning Toluca Lake, CA

Restaurant Ventilation Cleaning Toluca Lake, CA

Professional Hood And Duct Cleaning Toluca Lake, CA

Kitchen Hood Service Toluca Lake, CA

Commercial Hood Installation Toluca Lake, CA

Hood Filter Replacement Toluca Lake, CA

Kitchen Hood Repair Service Toluca Lake, CA

Commercial Kitchen Hood Installation Toluca Lake, CA

Kitchen Hood Inspection Toluca Lake, CA

Near Here Seo Company Toluca Lake, CA

Near Here Seo Citations Toluca Lake, CA

Instant Air Solutions

Table of Contents

- – Kitchen Hood Service Toluca Lake, CA

- – Instant Air Solutions

- – Hood Filter Cleaning Toluca Lake, CA

- – Kitchen Hood Inspection Toluca Lake, CA

- – Kitchen Hood Service Toluca Lake, CA

- – Restaurant Hood Installation Toluca Lake, CA

- – Commercial Hood Cleaning Service Toluca Lake...

- – Professional Hood And Duct Cleaning Toluca L...

- – Hood Cleaning Companies Toluca Lake, CA

- – Kitchen Exhaust Cleaning Service Toluca Lake...

- – Restaurant Hood Cleaning Service Toluca Lake...

- – Fire Suppression System Certification Toluca...

- – Kitchen Exhaust Fan Repair Service Toluca La...

- – Hood Filter Replacement Toluca Lake, CA

- – Fire Suppression System Certification Toluca...

- – Instant Air Solutions

Latest Posts

24 Hour Emergency Plumber Near Me Mira Mesa

247 Plumber Near Me Rancho Santa Fe

Plumbing Company Near Me Carlsbad

More

Latest Posts

24 Hour Emergency Plumber Near Me Mira Mesa

247 Plumber Near Me Rancho Santa Fe

Plumbing Company Near Me Carlsbad